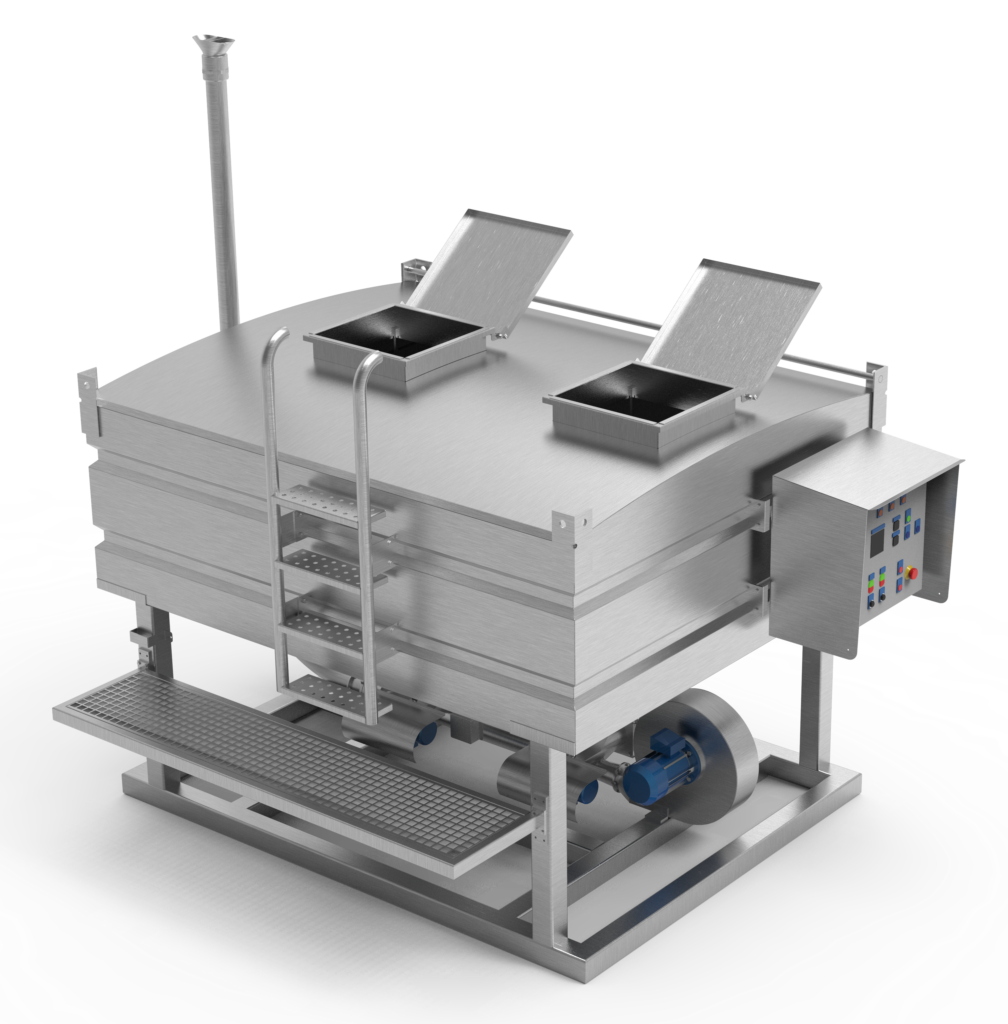

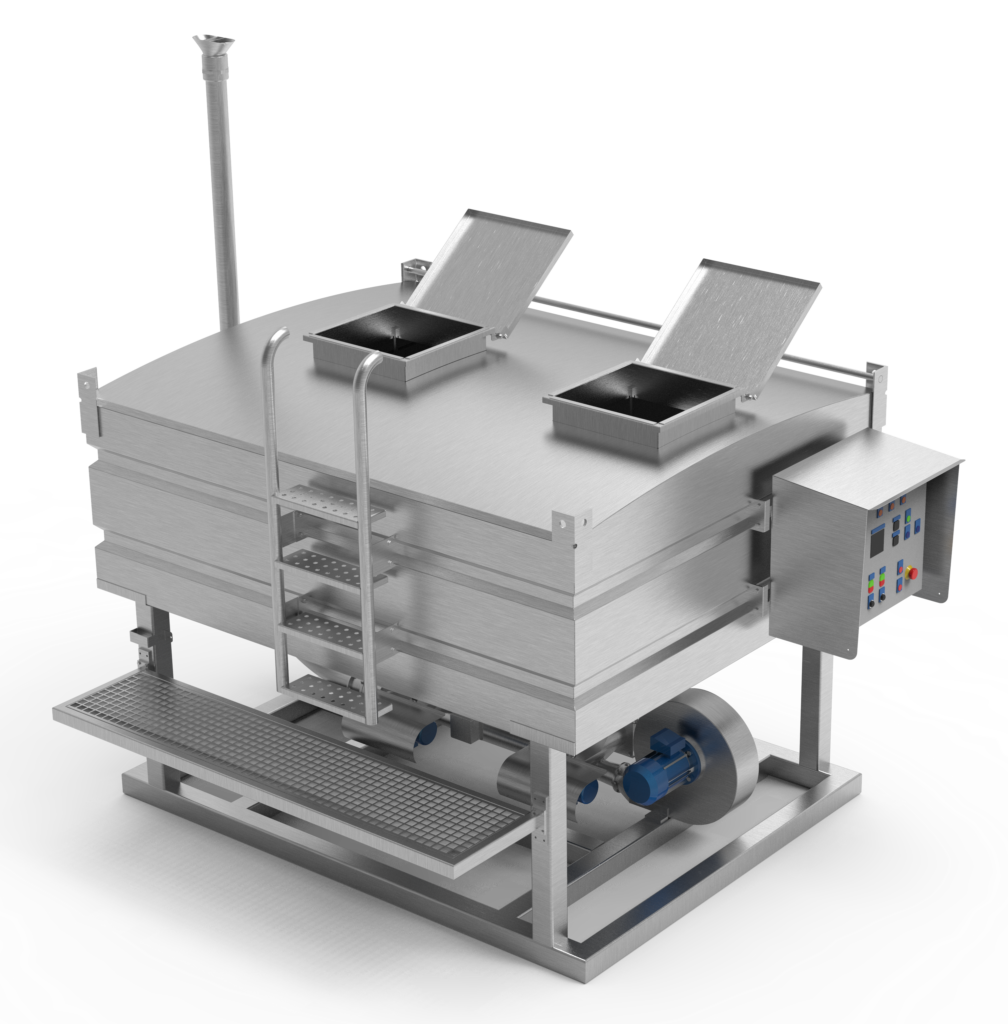

THE PERFECT GUTTING MACHINE FOR SMALL AND MEDIUM SIZE PRODUCTION PLANTS

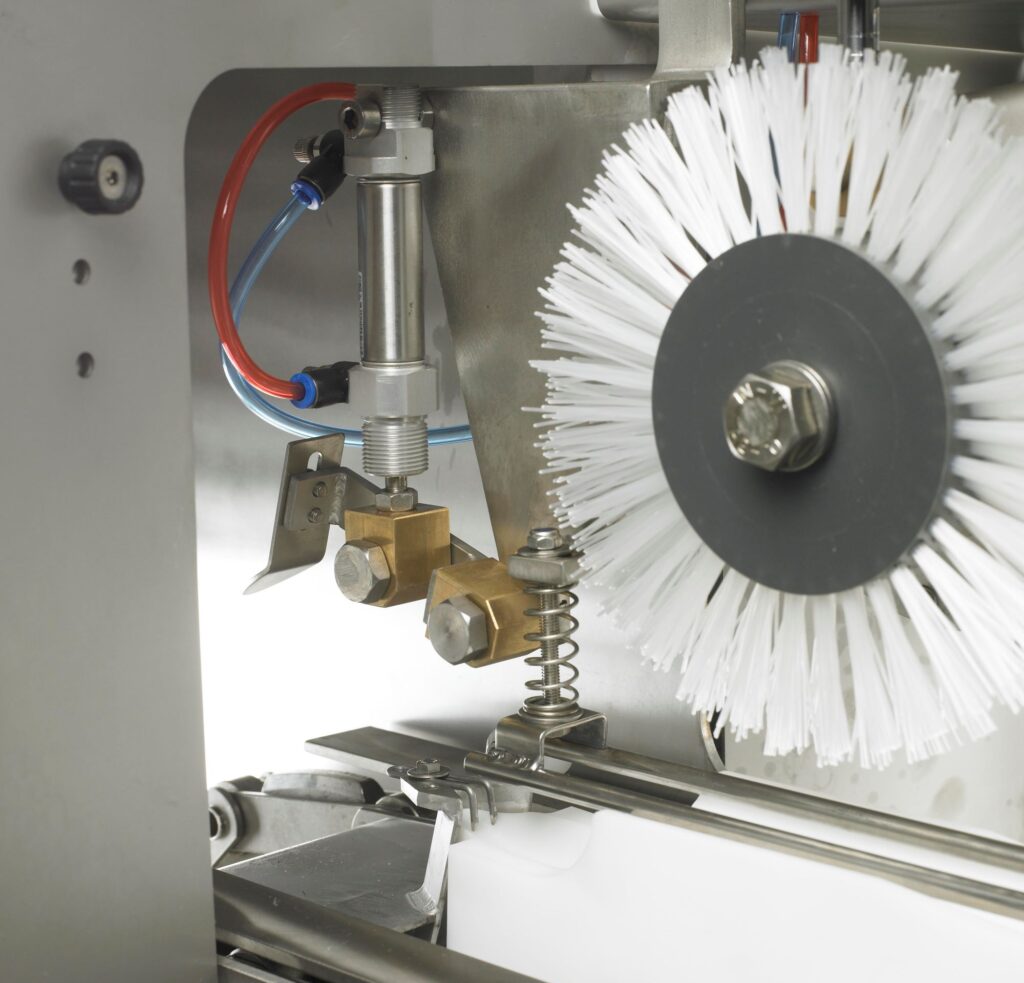

The gutting of fish must be thorough, but at the same time the machine must be easy to maintain, flexible to adjust and suitable for different types of fish. In a few words, that is the GUTMASTER 750.

An example is GUTMASTER 750 intended for sea bream and sea bass, two very different types of fish, which are often bred at one and the same fish farm. The gutting machine can be used on both these fish types thus minimizing the cost for machine investment.

Production setups where GUTMASTER 750 comes into its own for real are those where there is little weight difference between the fish that are intended for processing. GUTMASTER 750 ensures uniform processing of all fish species, but with added high level of precision because of the built-in controls in the machine.

The machine can be supplied for a number of different fish species, with the latest addition being tilapia.

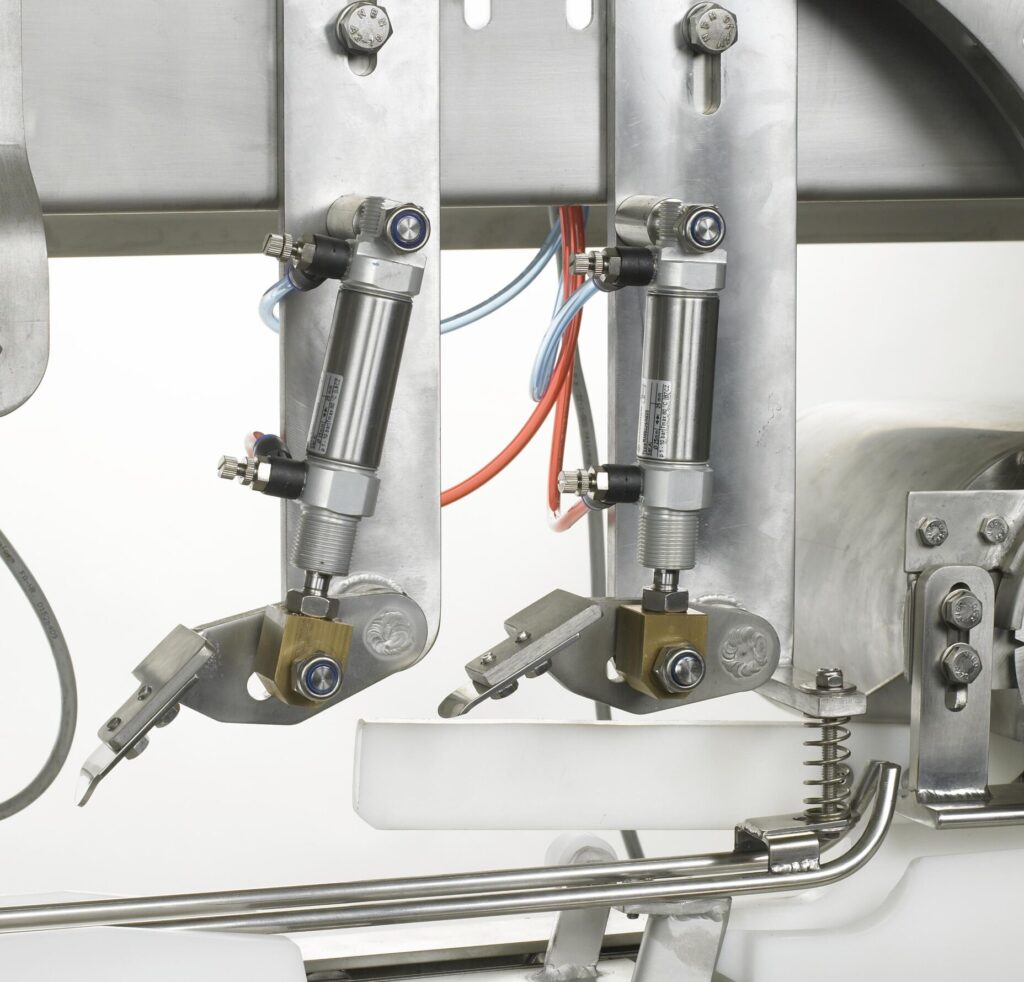

Each fish species has its own individual skeleton or meat structure, which is why individual machines can be built in very different ways.

• Fully Stainless steel construction including silo, blowers and dosing system.

• Fully Stainless steel construction including silo, blowers and dosing system.

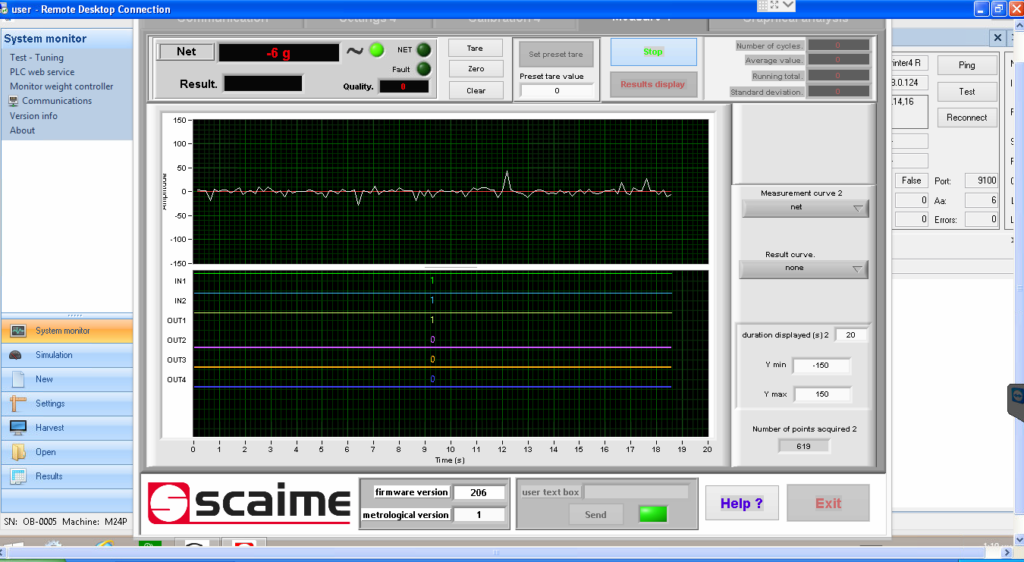

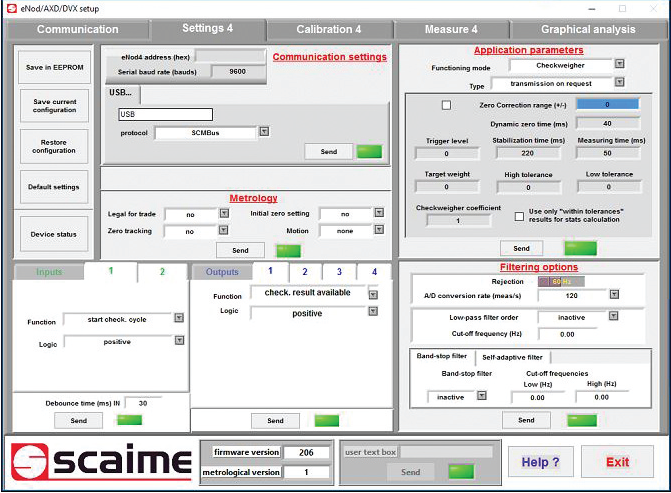

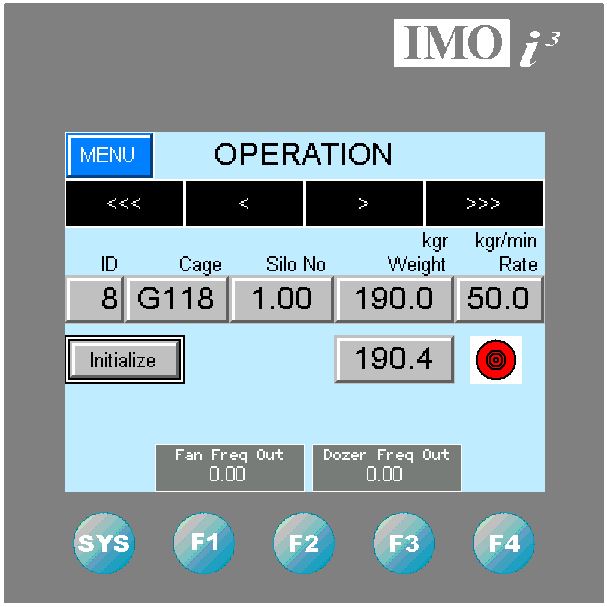

Software

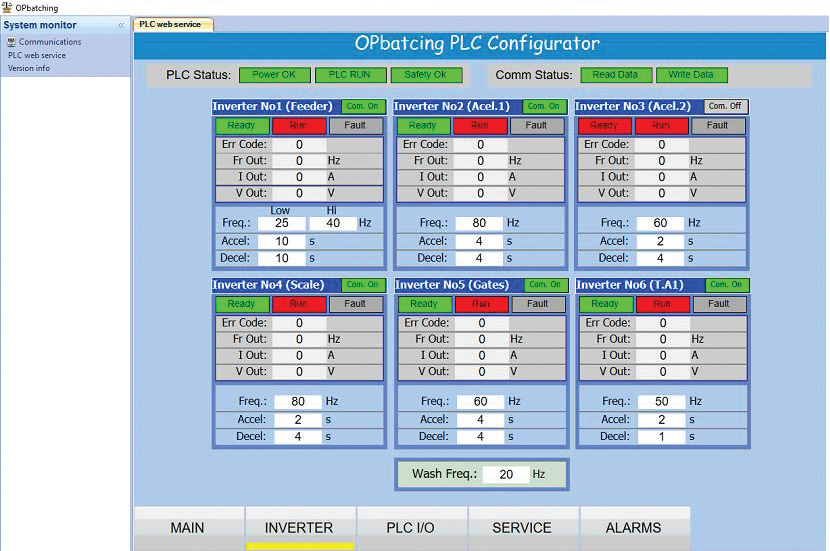

Software